SFG

SFG

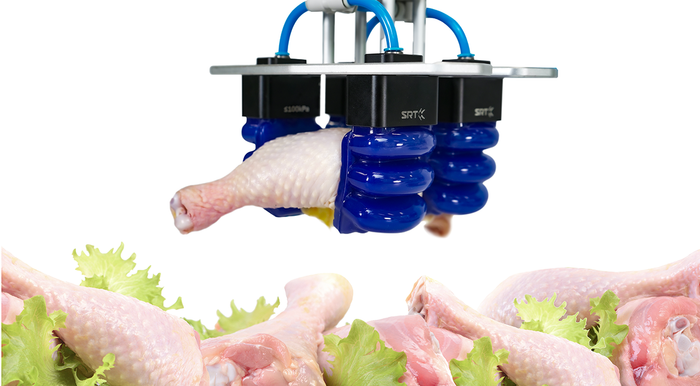

Application Of SFG In Meat Picking

SFG flexible grippers can work day and night in a variety of harsh environments, such as wet cold rooms, hot, high temperature workshops. When production demand suddenly increases due to seasonal changes, it can flexibly adjust the rhythm of the production line without the need to hire additional temporary workers. Moreover, it is flexible and easy to set up, can quickly adapt to new products or new processes, improve work efficiency. The finger of SFG is made of food-grade silicone, which not only successfully passes the two-way strict testing and certification of FDA in the United States and JFSL370 in Japan,...

Read More

SFG-S Is Suitable For Operation In Dust And Oil Pollution Environment

In the catering industry, there is a wide variety of ingredients, from delicate and easy to loose sushi to a wide variety of side dishes, each with its own unique handling needs. Among them, maintaining food hygiene is the top priority in the production process, and cleaning work is the key to preventing pollution. To this end, we have introduced SFG-S food-grade fixtures as a solution. The fixture's connectors are covered with...

Read More

SFG_MVG Egg Food Sorting Application

In the field of food sorting, especially for products like eggs that are extremely sensitive to grasping methods, choosing the right fixture is crucial. Our SFG (Soft Finger Gripper) flexible gripper uses advanced soft robotics technology with soft pneumatic "fingers" that can be adapted to...

Read More

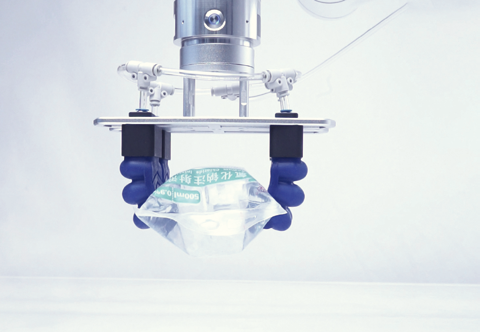

SFG Improves The Sorting Efficiency Of Medical Consumables

There are many kinds of medical consumables, from disposable syringes, catheters to soft medical fabrics, etc., each of which is different in material, size and shape, which puts extremely high requirements on sorting work. Manual sorting is not only inefficient, but also prone to error, and SFG flexible grippers can reduce this error rate and the risk of cross-infection, improving the quality and safety of medical services. For vulnerable medical materials,...

Read More

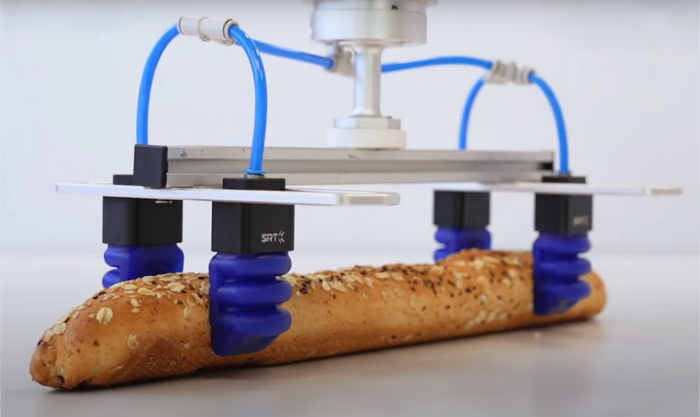

SFG Improves Pastry Automation

In the process of automated pastry processing, the challenges include the soft and fragile nature of the product, the easy peeling of the surface, the chocolate coating marks, and the inconsistency of the product form, size and weight. To address these challenges and reduce pastry breakage, SFG flexible grippers are recommended for efficient sorting. SFG grippers have been approved by the US FDA and Japan's JFSL370 standard,...

Read More

SFG Enhances The Efficiency Of 3C Electronics Production

In the 3C electronics industry, rapid iteration and complex processes place greater demands on production flexibility and precision. Although the traditional 2D visual sorting scheme is effective, the recognition time is long, which...

Read More

SFG Accurately Responds To Diverse Commodity Sorting Challenges

According to statistics, the workload of sorting accounts for about 40-60% of the workload of chain supermarket distribution centers. With the continuous increase of commodity SKU types, traditional manual sorting alone will not be able to meet the requirements of large-scale sorting and distribution, and flexible claws can solve...

Read More